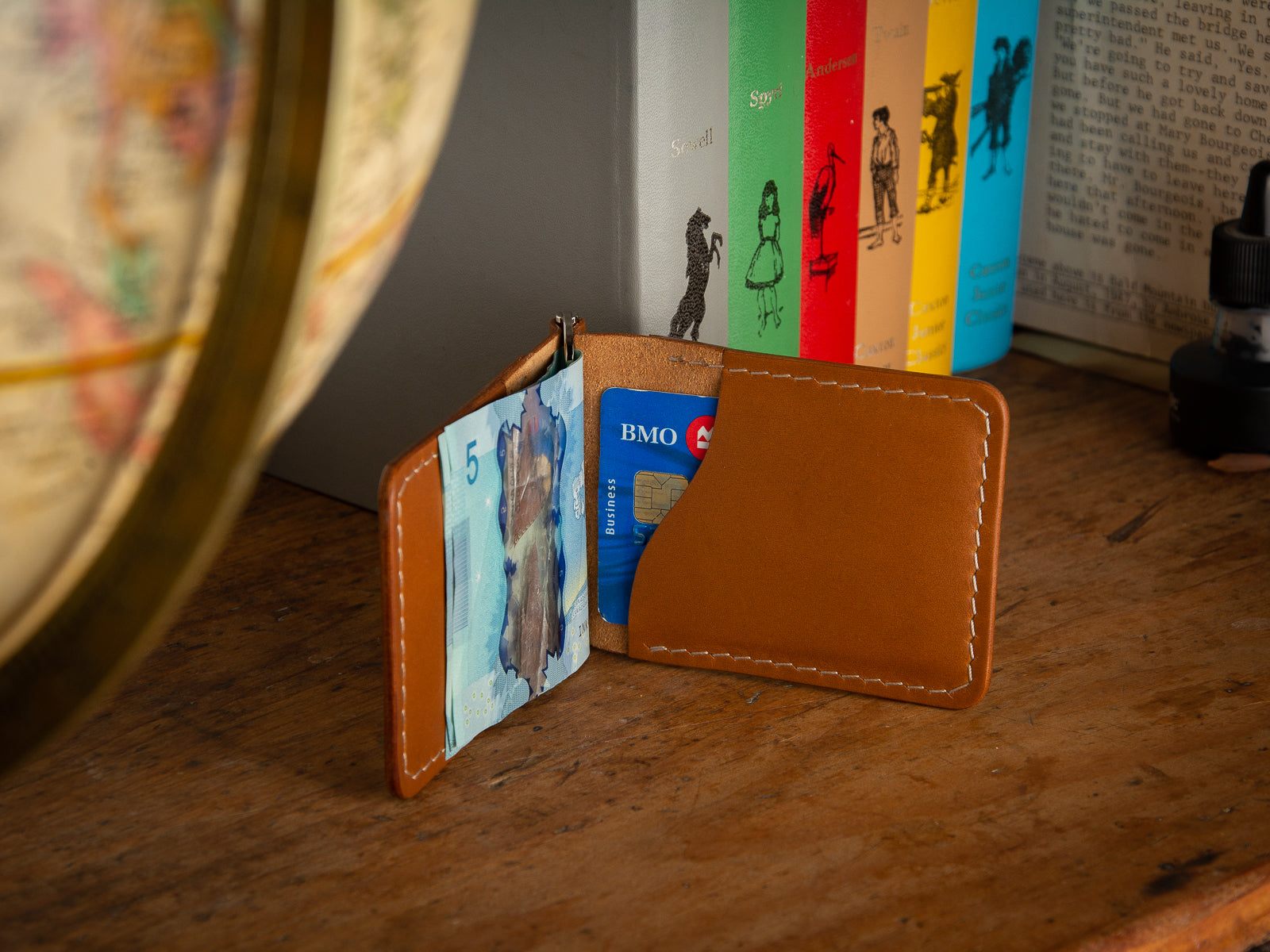

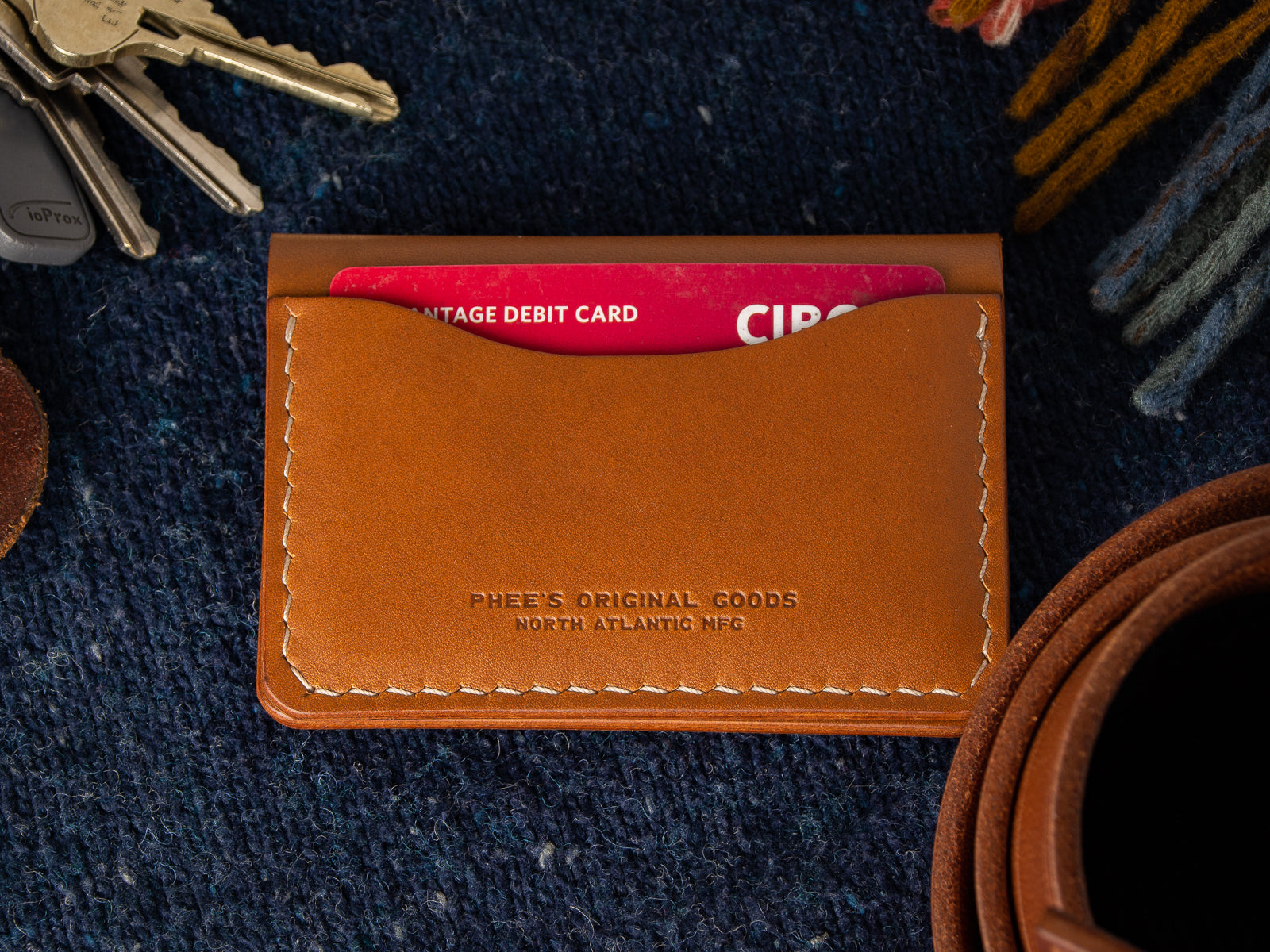

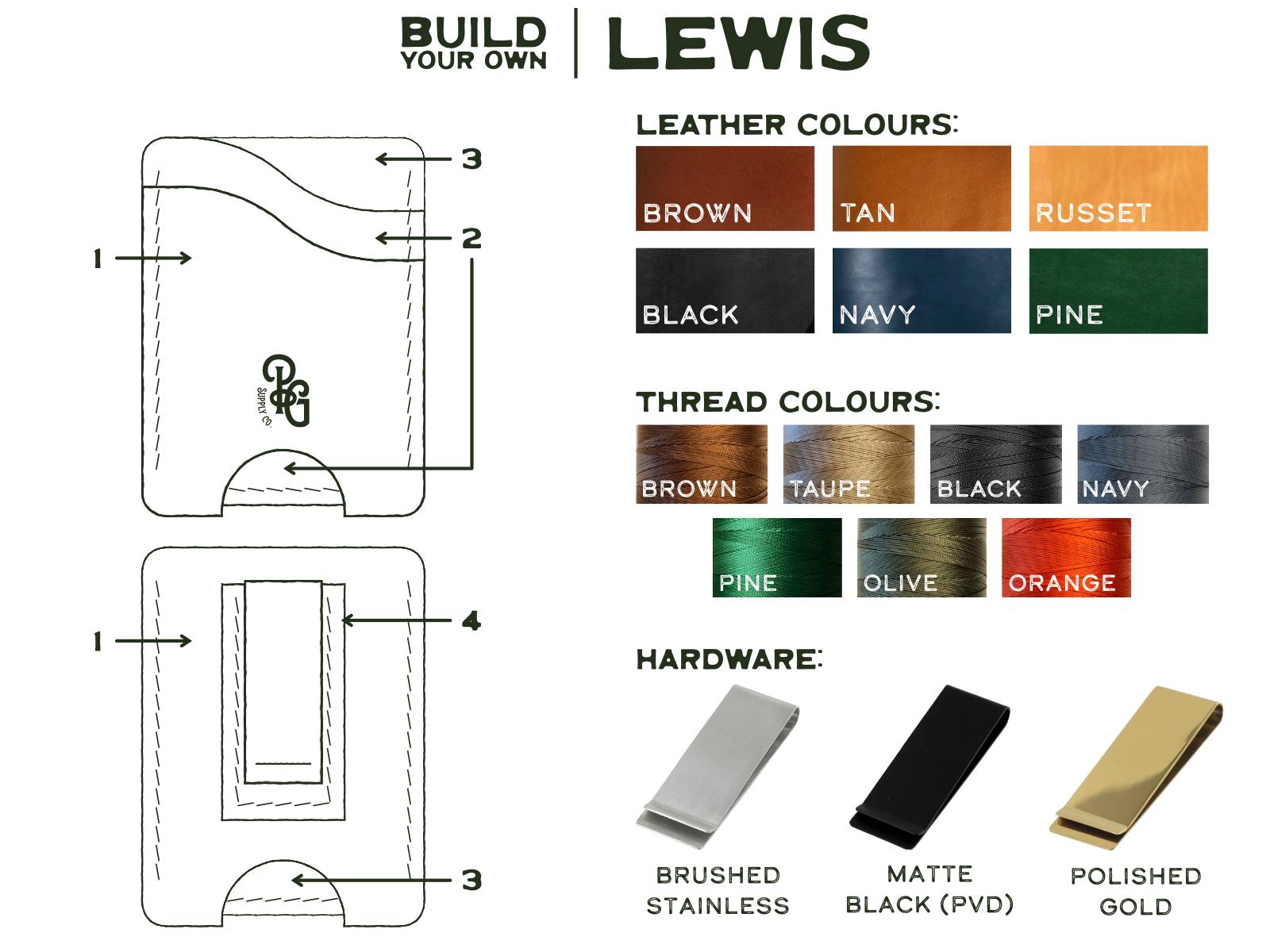

a wallet for every pocket

.

how we make your wallet

Cutting

We start out with a full double-shoulder of the finest italian vegetable-tanned leather. With it's firm temper, soft back and consistent face, it's ideal for building wallets. Each pocket is either hand cut, or cut with a custom-made die using our clicker press.

bevelling + burnishing

The edge of every pocket and piece is bevelled and burnished by hand. This not only speeds up the patina process, but also leaves the edges super smooth for comfort and ease of use.

Skiving + Glue Up

We use a skiver to reduce the bulk of certain parts of your wallet to minimize it's feel in your pocket and maximize it's function. Next, we glue up the pockets before they're ready to be handsewn.

Punching + Sewing

Each stitch hole is punched by hand with pricking forks. We hand sew the wallets, using the tried-and-true saddle-stitch technique.

The finished goods

Easy as that! It's ready for life in your pocket.

We print + assemble our packaging in-house, write you a little love note, pack it all up and send it off with one of our trusty couriers.

Let customers speak for us